The metalworking industry is a critical sector that is largely supported by an array of specialized machines. These machines help to shape, form, and assemble metal components, which are used across various industries. This article provides an overview of 11 key machines used in the metal working industry.

I. CNC Milling Machine

The CNC (Computer Numerical Control) Milling Machine is an equipment controlled by a computer program. It has the ability to cut and shape metals in three dimensions, making it a vital tool for complex metalworking projects.

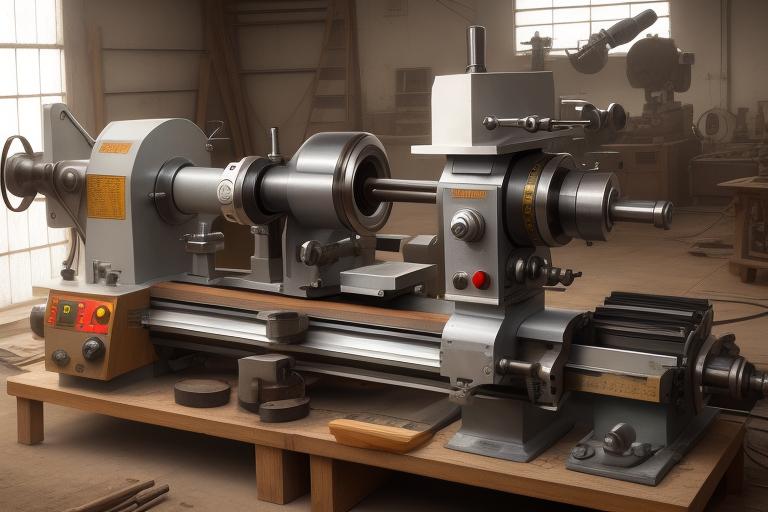

II. Lathe Machine

The Lathe Machine is one of the oldest metalworking tools, and its basic design hasn’t changed for centuries. This machine can hold and spin a piece of metal while a cutting tool shapes it.

III. Drill Press

A Drill Press is used to make holes in metal pieces. With its controlled speed and depth, precision drilling in metals is guaranteed.

IV. Grinding Machine

The Grinding Machine uses an abrasive wheel as a cutting tool. This machine grinds away the surface of a metal workpiece, producing a smooth finish.

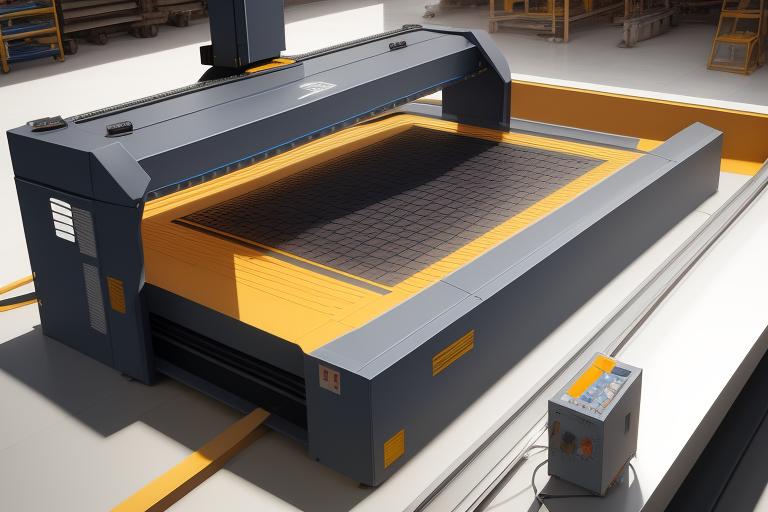

V. Laser Cutting Machine

A Laser Cutting Machine uses a high-powered laser beam to cut precise shapes in metal. This technology is commonly used for mass-producing metal objects with complex shapes and designs.

VI. Welding Machine

The Welding Machine is used to join two pieces of metal together. There are various types, including arc welding, gas welding, and laser welding machines.

VII. Sheet Metal Machine

The Sheet Metal Machine is used to cut, bend, and join thin sheets of metal. This machine is critical in the fabrication of sheet metal products.

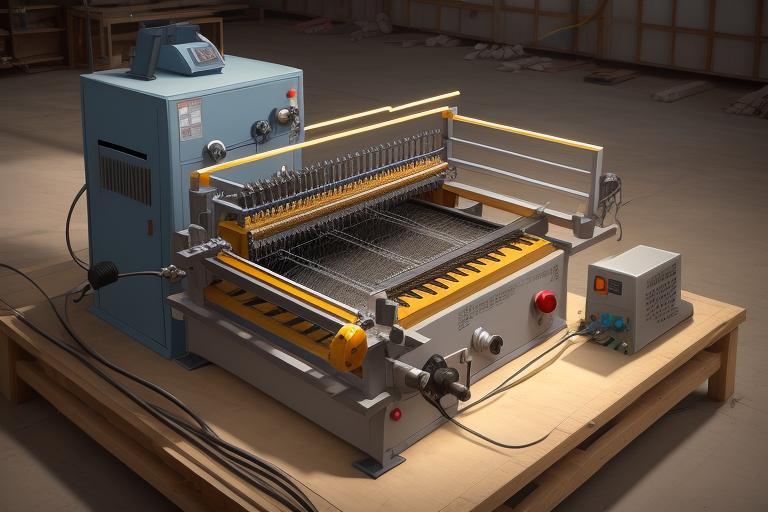

VIII. Wire Bending Machine

A Wire Bending Machine is used to bend wires or strips of metal into specific shapes, which could be either simple or complex.

IX. Press Brake

The Press Brake is used to bend heavy sheets of metal. It’s an essential machine in industries such as shipbuilding and heavy equipment manufacturing.

X. Plasma Cutting Machine

Plasma Cutting Machines cuts metal with a high-temperature, electrically conductive gas. This machine offers precision and efficiency in cutting metal.

XI. Broaching Machine

The Broaching Machine is used for precision machining, cutting, and shaping metals. It can be used to work on both flat and round metal pieces.

In summary, these 11 key machines form the backbone of the metalworking industry, making it possible to manufacture all kinds of metal products that are used in various sectors including construction, automotive, aerospace, and many more.