Whether you’re an experienced professional or relatively new to the field, distinguishing among the various Computer Numerical Control (CNC) systems out there is key to understanding their capabilities and limitations. This guide aims to demystify the various types of CNC systems to give you a clearer picture of this world.

Stand-Alone CNC Systems

Stand-alone CNC systems are unique in that they perform all CNC functions in a hardware unit independent of any other system. They contain their computing and control systems, which are dedicated solely to manufacturing tasks. The primary advantage of stand-alone CNC is their reliable and robust performance in a wide range of industrial environments.

CNC Machining Centers

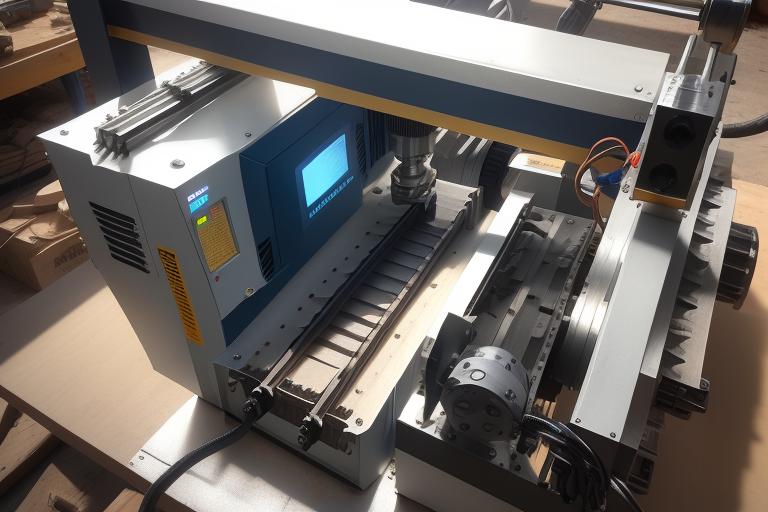

CNC Machining Centers are highly versatile and capable of performing a wide variety of tasks. These systems are equipped with multiple tools and axes, enabling them to perform many operations like milling, drilling, boring, and tapping in a single setup. There are several types of CNC machining centers, including vertical, horizontal, and multi-tasking systems.

CNC Turning Centers

CNC Turning Centers are primarily designed for turning operations. They are equipped with spindle speed variation, live tooling capabilities, and even secondary spindles for back-end machining. They are highly popular due to their wide range of capabilities and excellent precision.

CNC Milling Machines

CNC Milling Machines are capable of performing complex cutting tasks. They use rotary cutting tools to remove material from a workpiece. Milling machines can be either horizontal or vertical, depending on the orientation of the spindle. CNC milling machines offer a high degree of versatility and accuracy, making them a popular choice for many manufacturing applications.

CNC Plasma and Laser Systems

CNC Plasma and Laser Systems are used for cutting materials with great precision. While plasma systems are typically used for cutting thick conductive materials like metal and steel, laser systems are used for cutting a wide variance of materials from metals to plastics to wood with extreme precision.

Summary

Understanding the different types of CNC Systems is crucial for anyone involved in manufacturing, engineering, or related fields. By having this knowledge, you can make more informed decisions about the type of CNC system that best suits your needs and applications, thereby maximizing efficiency and precision in all your work.