Choosing the right laser machine for your specific use can often seem a challenging task given the variety of technologies and application methods. This guide is designed to help readers differentiate between laser engraving, laser etching, and laser marking machines. We will explore each one’s meaning, process, pros & cons, and the applications for which they are best suited.

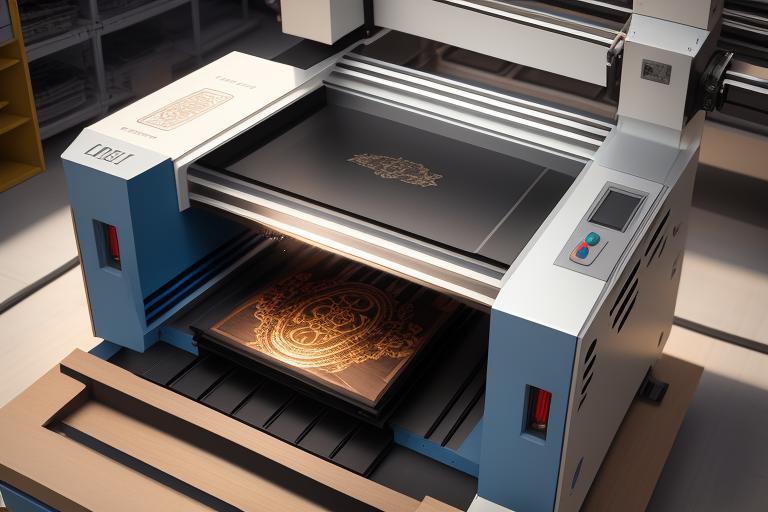

Laser Engraving Machines

Laser engraving is a process where the laser beam physically removes the surface of the material to expose a cavity that reveals an image or shape at an eye level. This method is most suited for creating high-quality graphics on almost any material, including metal, glass, plastic, and wood. It’s also commonly used for personalizing objects and crafting unique designs.

Laser Etching Machines

Laser etching, on the other hand, takes the process a step further. This technique involves melting the surface of the material, which expands and causes a raised mark. It’s generally used on bare, anodized, or plated metal surfaces, ceramics, or polymers. Laser etching is advantageous in marking parts that undergo high wear, such as tools or control panels.

Laser Marking Machines

Laser marking is a broad term that includes both engraving and etching. It stands to describe a series of methods that leave marks on the material’s surface without altering its properties. When specialists talk about laser marking, they generally refer to annealing, carbon migration, color change, or foaming. It’s best used for parts identification, traceability, and branding.

In conclusion, understanding the differences between laser engraving, laser etching, and laser marking machines can be of great assistance when making your purchase decision. Choosing the right machine means understanding your application needs, material characteristics, and desired final product.